Been noodling around with various improvements to the cubesat structure, and started on revisions from the second prototype that would accomodate the Z- face requirements for springs and deployment switches. This new design with prototype 3 had a more complex structure for the Z- component tray, and it quickly became difficult to envision simple fabrication.

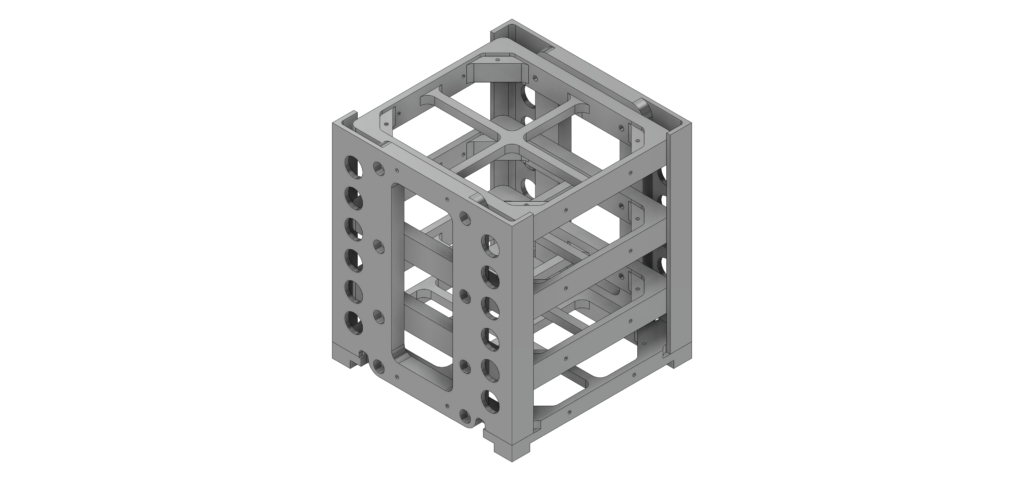

I decided to start over with a completely different concept. Instead of four vertical columns (pillars) for mounting I opted for the Y- and Y+ faces to have the rails “built into” their structure. This iteration is starting to look more like a solid design that can be easily fabricated either by myself or one of the low-cost custom manufacturing companies out of China. I’ve used JLCPCB for circuit boards in the past and been very happy. Their CNC service looks equally reliable and low-cost.

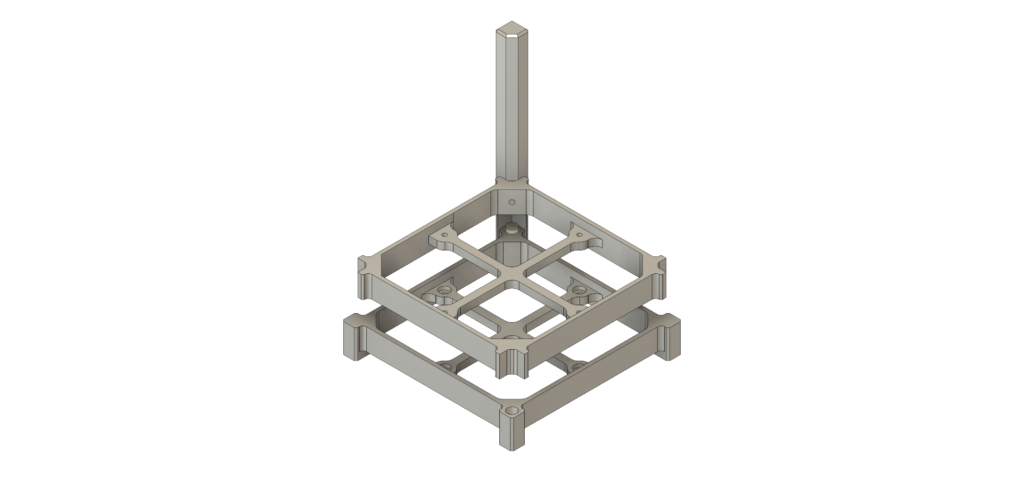

Prototype 4 with a complete model. Its not fully designed but I think this is workable enough to try printing in plastic.

I’ll post some pictures of the 3D printed version in the next post, after I’ve been able to print it.

From the calculations in Fusion 360, assuming aluminum 7075:

| Component | Mass |

|---|---|

| Z- face structure | 62.927 grams |

| Y- and Y+ face structures | 98.188 grams each |

| Tray 2 – 4 | 75.299 grams each |

| Total mass | 485.2 grams |

So nearly 25% of the mass budget is (currently) dedicated to the structure. This doesn’t include bolts (currently spec’d to use 16x M3 and 40x M2) which will add around 15 grams.

There is certainly easy ways to reduce this a bit: drill some additional holes in the thicker parts of the Y-/Y+ structures, use fewer bolts, etc.

Four 18650 cells will add close to 200 grams. This leaves about 1,300 grams for circuit boards, electronics, camera(s), antenna(s), etc.